Hello RETs! I have been a little MIA but that’s because I have been getting the full research experience: I’ve been in the lab all day, running multiple trials and reading literature. Needless to say I have a GREATER appreciation for science and the scientist who spend their time doing research – it can be a lot – so shout to all my researchers and THANK YOU for your contribution!

Pyrolysis Treatment

Pyrolytic treatment of crude-oil contaminated soils offers great potential for rapid remediation (for contamination) with lower energy requirements than incineration. And it does not require the presence of oxygen but rather nitrogen which is already abundant in our air.

Process

Step1 :

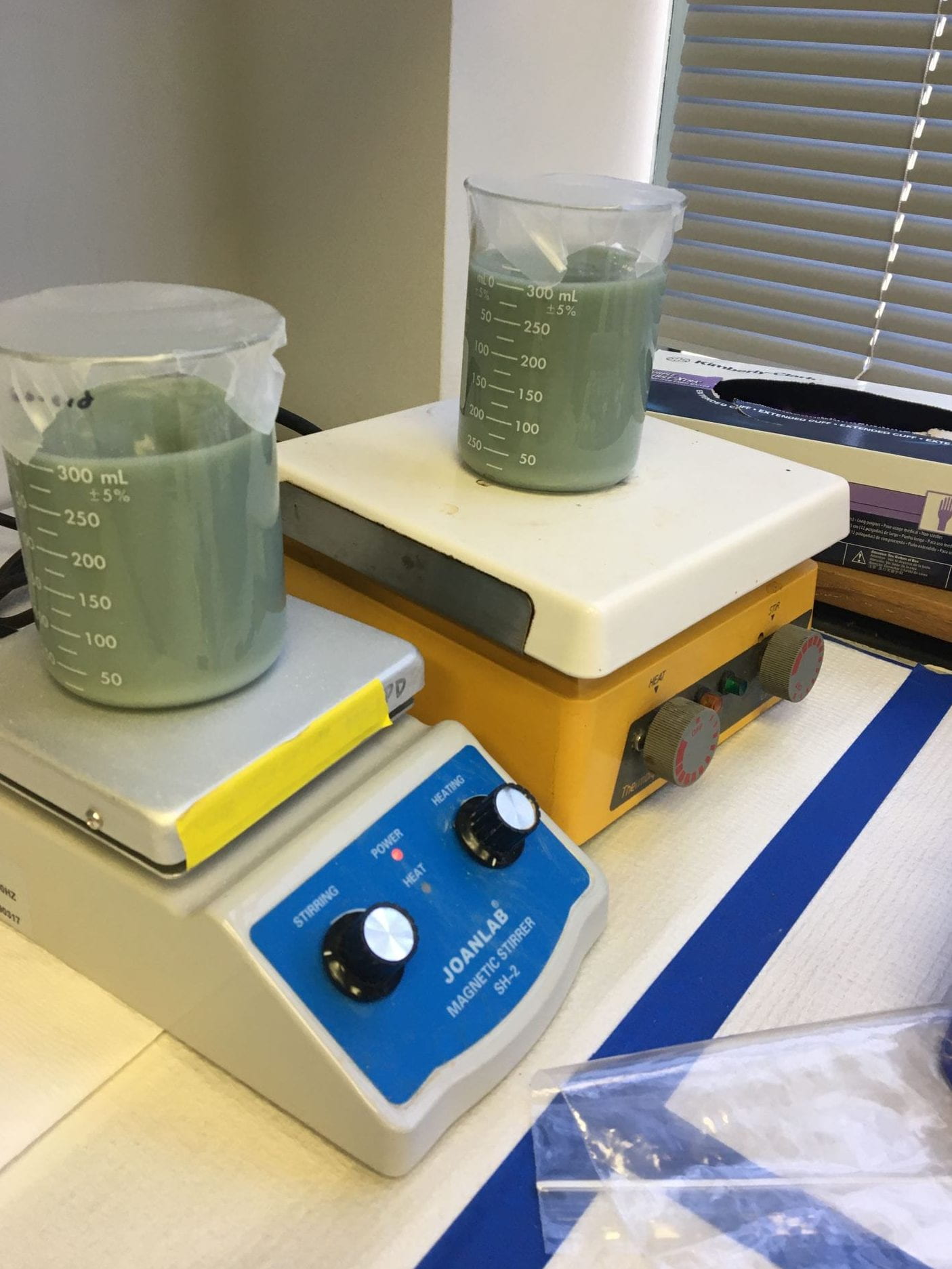

Ion-exchange (Fe(III) Nitrate + Benotnite; Cu(II) Nitrate + Benotnite) Metal with DI water, stir for 5 minutes, then add water (ORDER MATTERS). Leave stirring for 24hrs.

Step 2:

Contamination of clays with 0.1% wt or 1000 mg/kg using pyrene C16H10 (aromatic hydrocarbon) hexacosane C26H54 (aliphatic/cyclic hydrocarbon) . Use appropriate solvent (acetone or hexane) for each contaminant.

Step 3:

Pyrolysis by setting a temperature between 328C and 330, running that at a rate of 11-15 degrees C/min and holding it for 15 minutes.

Step 4:

Extractions, converting our solid product into a solution using a drying agent and mix of acetone and hexanes using an Accelerated Solvent Extractor (ASE).

Step 5:

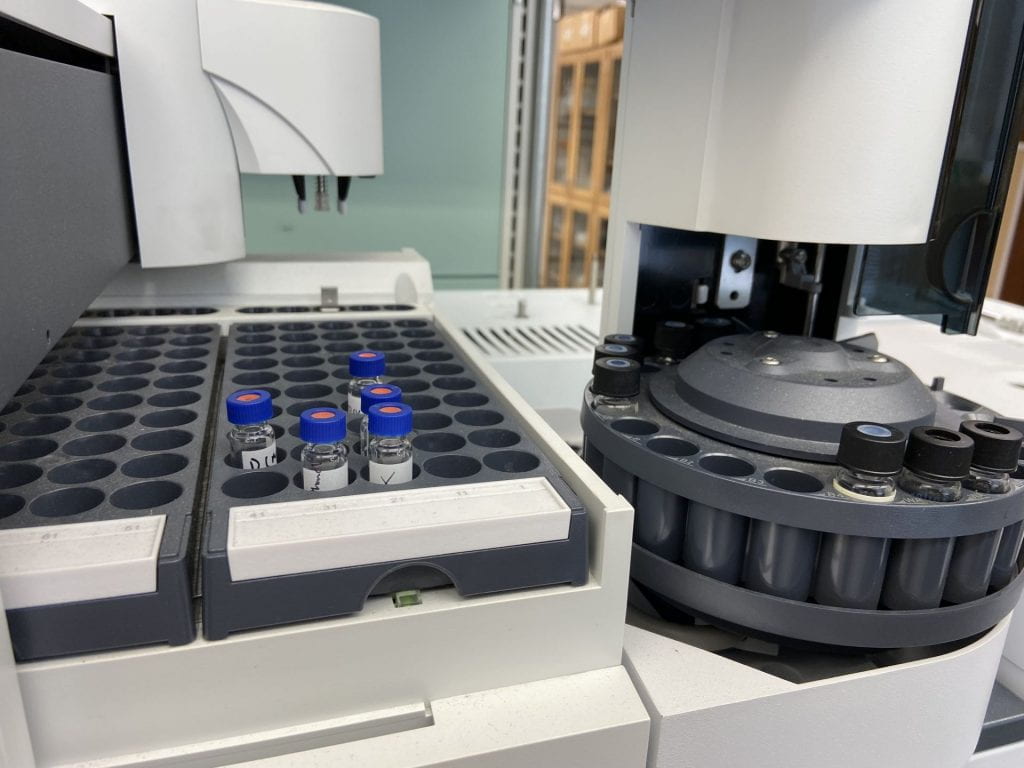

Gas chromatography–mass spectrometry (GC-MS) used to identify PAHs and other chemicals in our samples using their atomic mass.

Lastly, I was walking around campus and notice these beauties – it’s the little things we should appreciate. LEONEL OUT!